A few examples spring to mind.

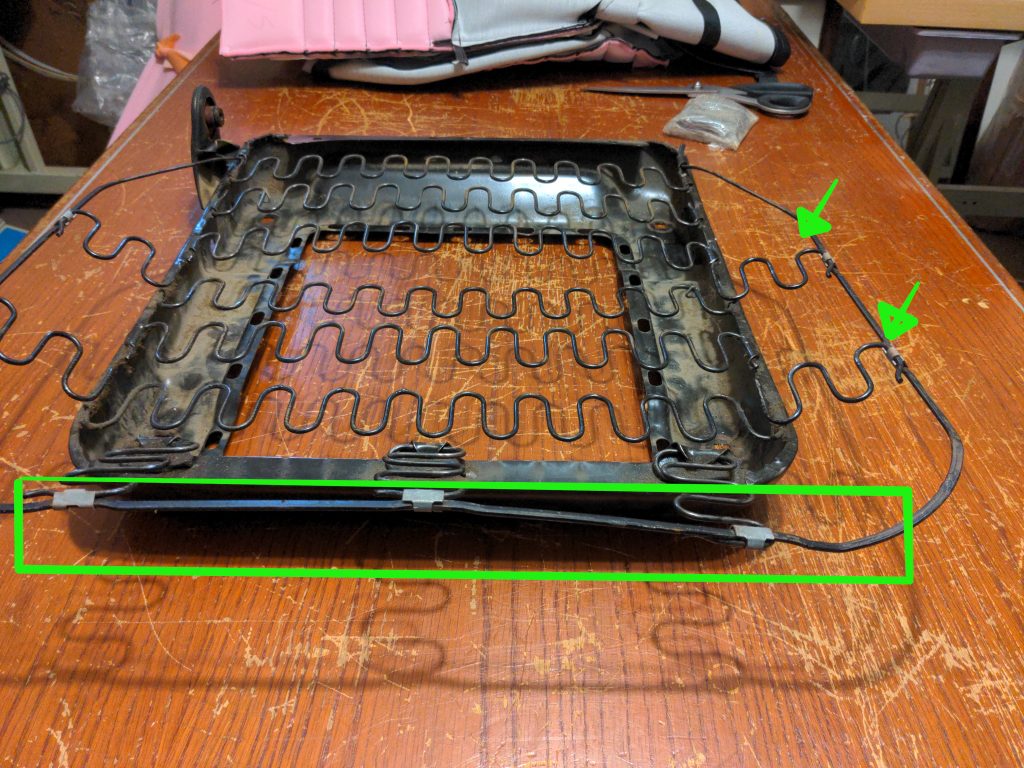

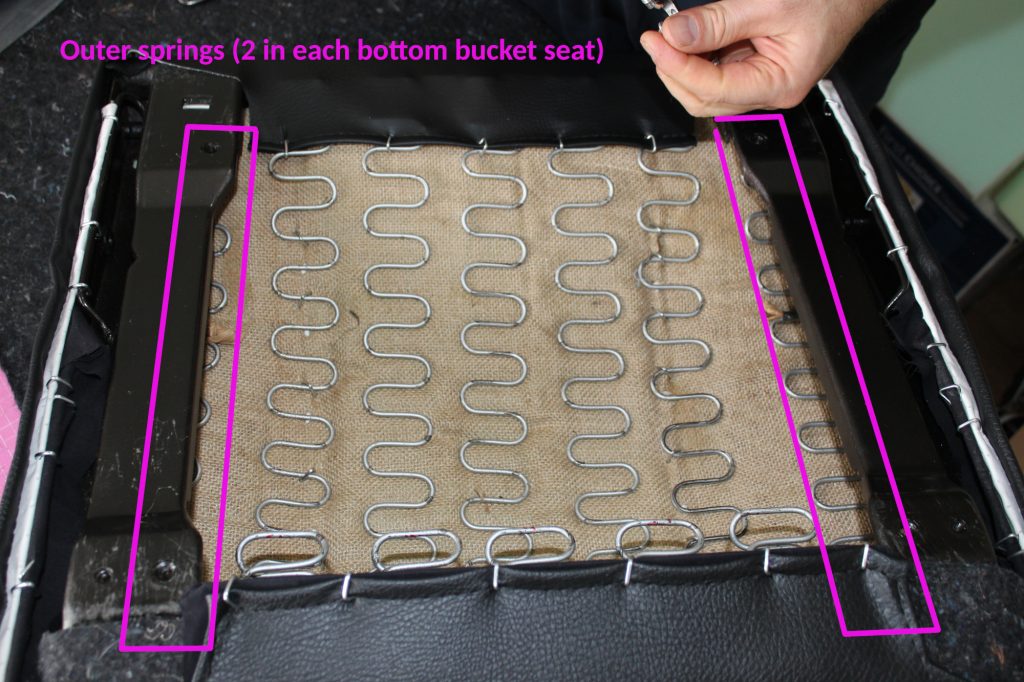

First, Ford XB. A few years ago we did a job for a customer who brought us a set of “unmolested” seats out of an XB fairmont hardtop. Upon inspection, the edge wire of the bottom seat had gone lop sided, and clearly the springs of that side had a fair amount of being used heavily as one would get in and out of the car a lot. The two springs are completely fatigued and way past their usefulness. They no longer function as springs should and would explain why seats like these – if not fixed properly – are extremely uncomfortable.

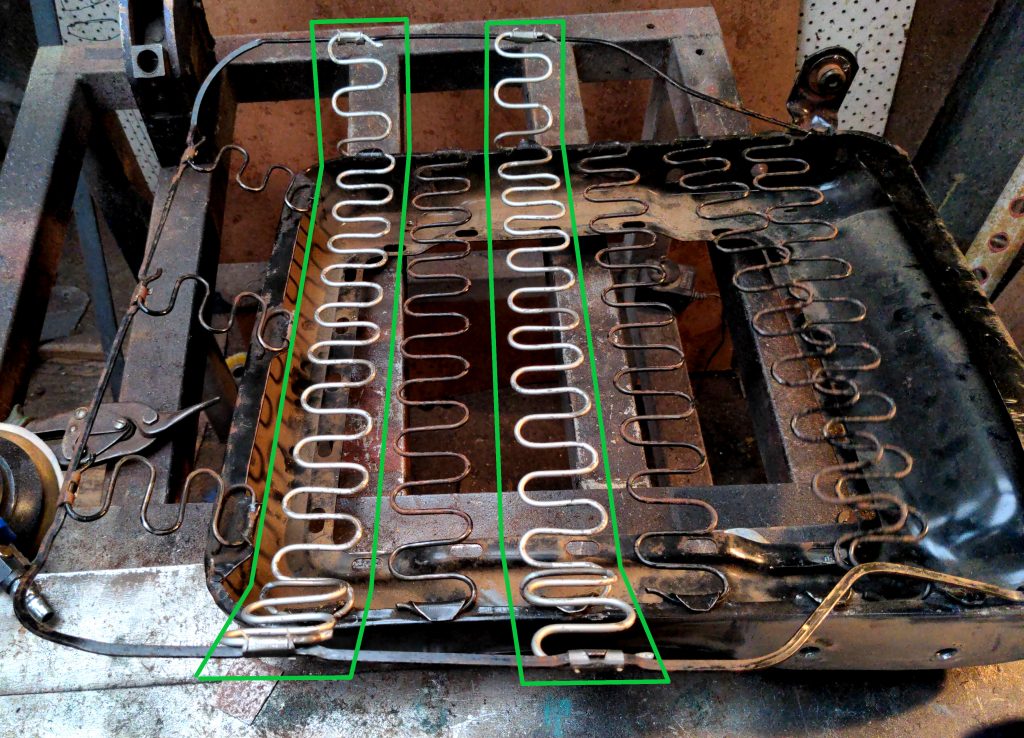

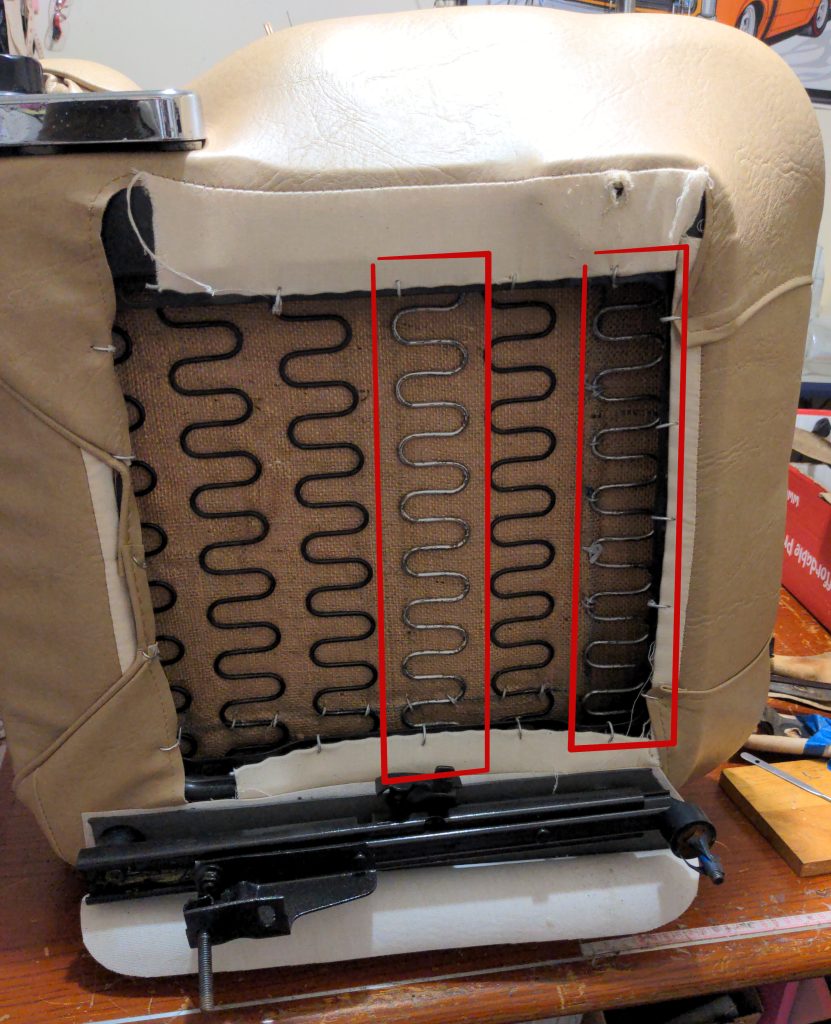

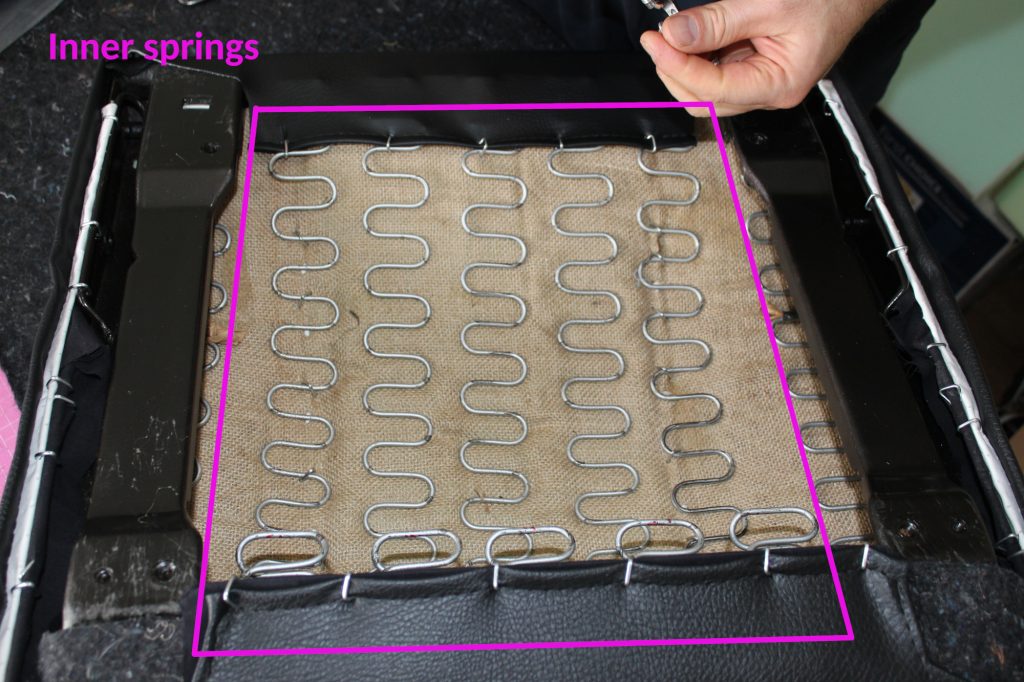

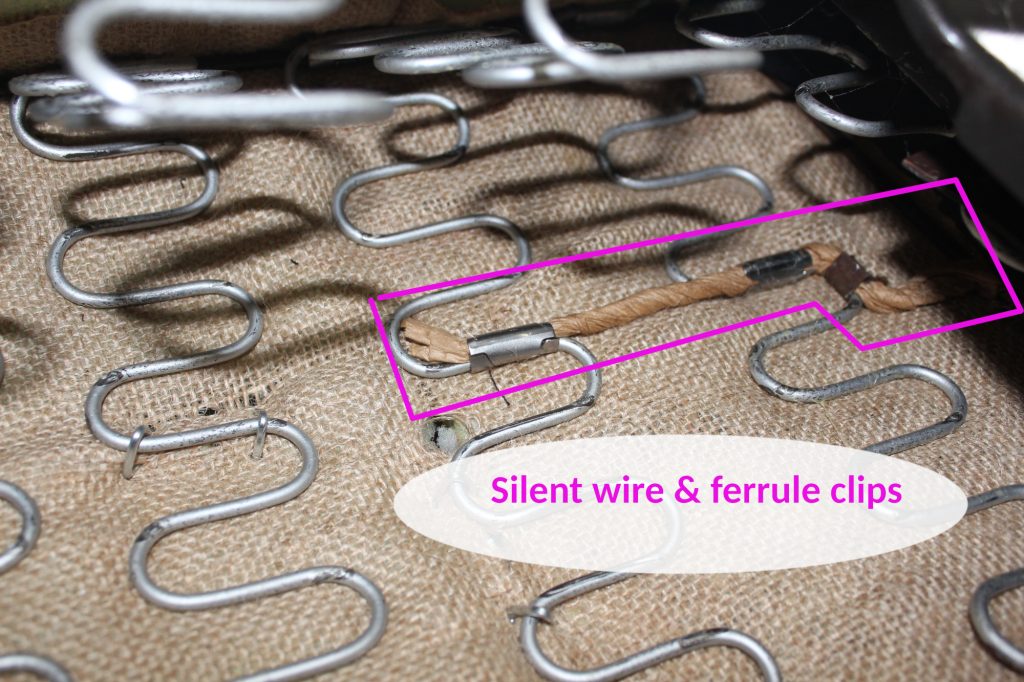

Another example is Valiant Chargers. These bucket seats have paper-covered wires (aka silent wires) from factory. The paper may seem insignificant, but they’re called silent wires because they reduce squeaky noises as the springs get sat on. The seats have these wires to connect and stabilise the zig zag springs. Although it may seem unimportant to replace the silent wires after blasting and painting seat frames, we believe taking the time to prepare the little things contribute hugely and positively to the overall job.

Finally, Valiant AP5 bench seats. A lot of bench seats have these more widely spaced springs; perhaps they were cheaper and quicker for the factory to manufacture them. The customer came to us because the springs were literally stabbing him in the back; they poked out of the seat foam and covers! We don’t like back stabbers either. We can’t buy this type of spring in a roll or in cut lengths. So these were all manually made up and put back into the seat before foam and skins are made. Read about it here.

Broken springs cannot be welded back together for obvious reasons. Fatigued springs also don’t do well for long even after new sections get joined via clips, because the new sections would add stress to the old with use, eventually leading to breakage.

While most people don’t worry about springs because they’re out of sight, we long ago found that we couldn’t properly obtain a good looking result without first fixing springs and then foam. Looks just aren’t everything. Our goal is to make seats as comfortable as they’re pleasing to look at.